Portfolio Insights - ENRX - Technology

Observing Operations with ENRX

ENRX is a global green tech company on a mission to speed up the journey to a sustainable future. By offering inductive heating, charging and power transfer with low or no carbon footprint – the forward-thinking company excels in technologies that provide value in manufacturing and mobility applications worldwide.

Est. reading time: 2 min

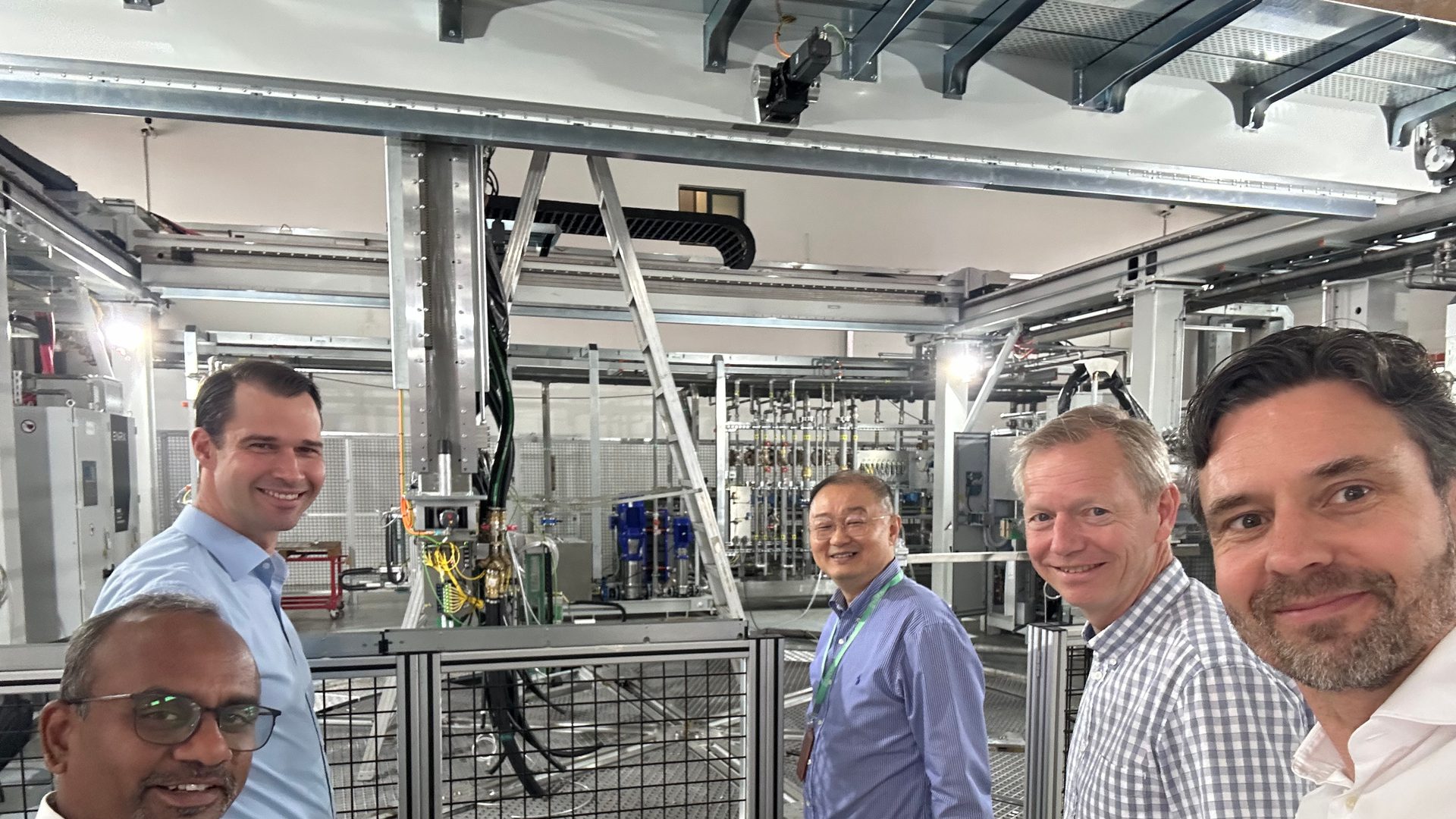

Recently, Arendals Fossekompani’s Executive Vice President, Håkon Tanem and ENRX’s CE0, Bjørn Eldar Petersen visited the production site for ENRX’s induction hardening machines.

Induction hardening uses induced heat and rapid cooling (quenching) to increase the hardness and durability of steel. It is a no-contact process that quickly produces intense, localised, and controllable heat.

“It was important to see how production works with my own eyes and observe the day-to-day routines while in China. This operation has consistently maintained a good reputation and it was a pleasure to meet the people that work there,” says Håkon.

“Our operation in Shanghai has over the years developed into the ENRX center of excellence for induction hardening machines. It is always a pleasure visiting ENRX China and watch the drive, competence, passion, and energy that can be seen and felt throughout this dynamic organization. It is a truly privilege to lead an organization of dedicated people in all parts of the world. Wherever you are – it feels like coming home,” says Bjørn.

Technology in focus

At the facility, induction is used to harden numerous components, such as: Gears, crankshafts, camshafts, drive shafts, output shafts, torsion bars, rocker arms, CV joints, tulips, valves, rock drills, slewing rings, and inner and outer races.

It is a fast and repeatable process that integrates easily into production lines. It is also clean, safe, energy-efficient, and typically with a small footprint.

Because each work piece is treated individually, ENRX can complete the operation with precise specifications. The technology is used to support automotive and wind power industries in addition to many others.

“ENRX’s factory is modern and designed to keep the focus on quality. It’s fascinating to witness all the influence that positively affected production facilities over the past twenty years,” says Håkon.