Our portfolio company, ENRX, is a new brand with decades of experience in induction heating, wireless inductive charging and contactless power supply. Previously known as EFD Induction- a company that was formed by the merger between FDF and ELVA in 1996. Today, it stands as a global leader of induction technology with operations in 20 countries.

How induction heating works

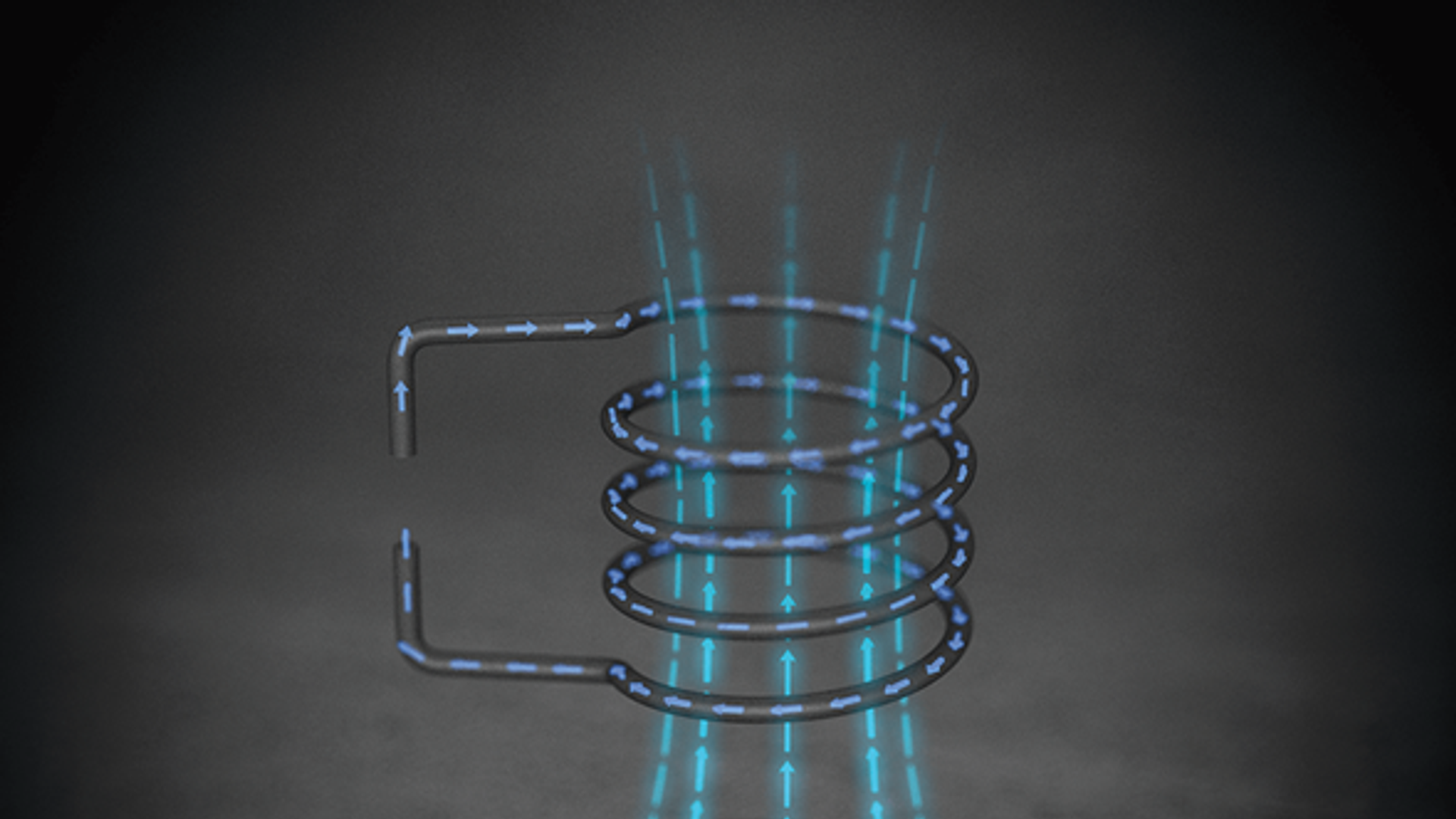

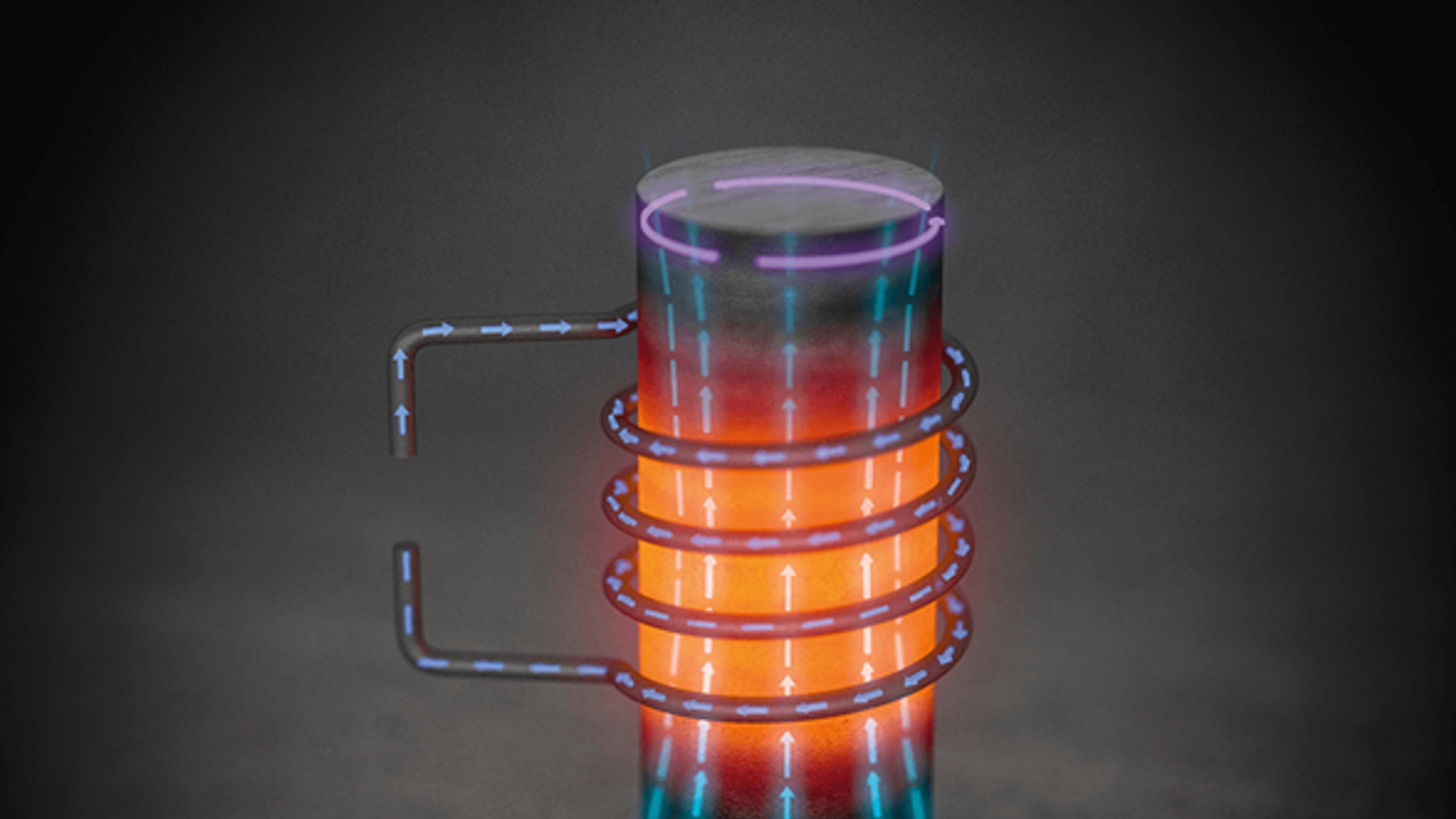

An induction heating system includes an induction power supply which converts line power to a higher frequency alternating current. Alternating current flowing through a coil generates a magnetic field. The strength of the field varies in relation to the strength of the current passing through the coil. The field is concentrated in the area enclosed by the coil; while its magnitude depends on the strength of the current and the number of turns in the coil.

Eddy currents are induced in any electrically conductive object—a metal bar, for example—placed inside the coil. The phenomenon of resistance generates heat in the area where the eddy currents are flowing. Increasing the strength of the magnetic field increases the heating effect. However, the total heating effect is also influenced by the magnetic properties of the object and the distance between it and the coil.

The eddy currents create their own magnetic field that opposes the original field produced by the coil. This opposition prevents the original field from immediately penetrating to the centre of the object enclosed by the coil. The eddy currents are most active close to the surface of the object being heated but weaken considerably in strength towards the centre. The distance from the surface of the heated object to the depth where current density drops to 37% is the penetration depth. This depth increases in correlation to decreases in frequency. It is therefore essential to select the correct frequency to achieve the desired penetration depth.

Maximize productivity and minimize energy consumption

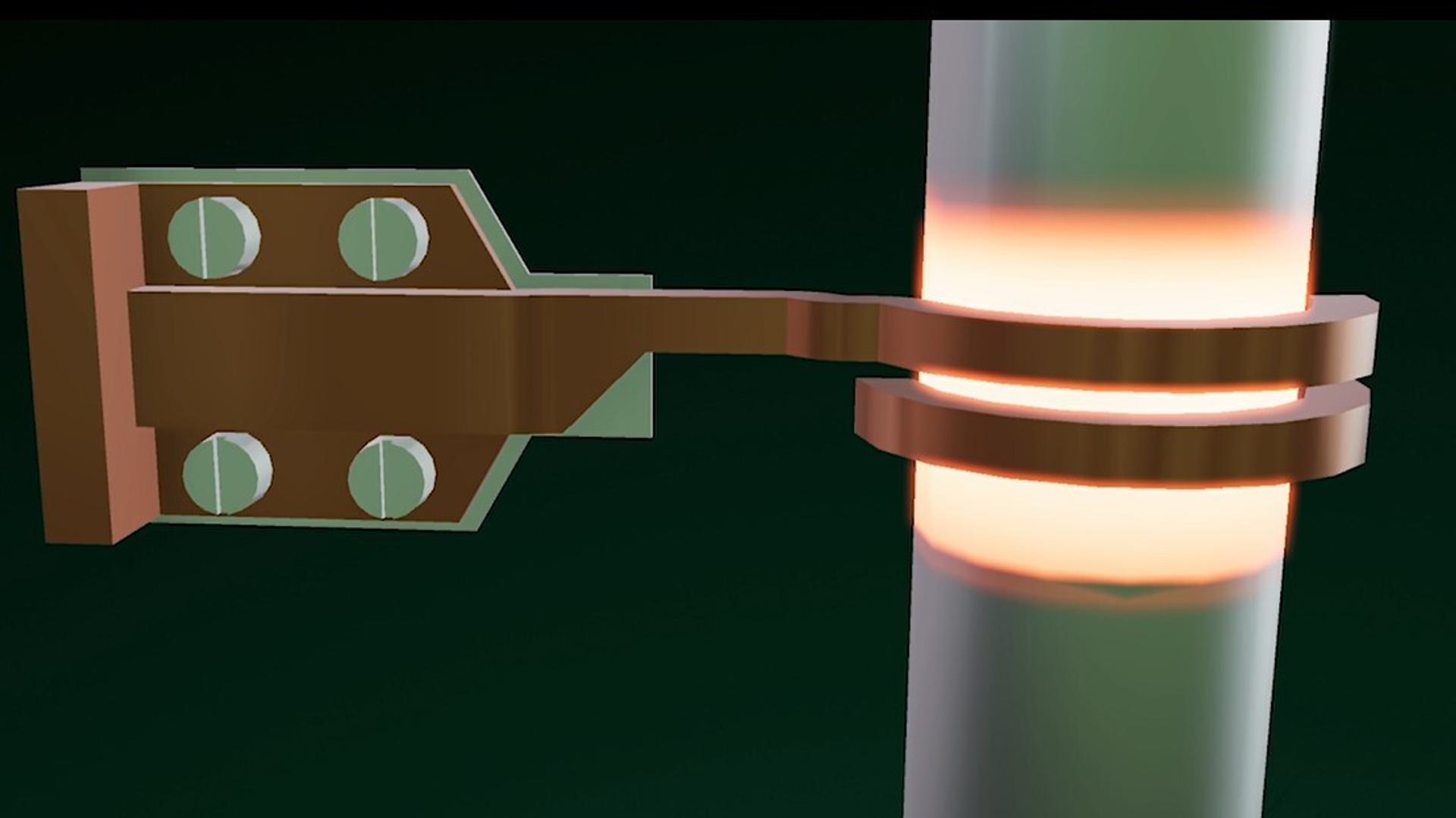

Coil design is one of the most important aspects of the overall system. A correctly designed and fitted coil will act as a customized solution to optimize equipment performance and save on energy used.

It is within the induction coil that the varying magnetic field required for induction heating is developed through the flow of alternating current. The efficiency of an induction heater is maximized if the work piece can be placed inside the induction coil. The size and shape of the water-cooled copper coil is designed to apply the heat to the correct place on the work piece.

ENRX offers a variety of coils for many applications (Conventional, 3D, Machined and Hybrid). From design and manufacture to repair and replacement – the company delivers high-quality coils that maximize productivity and minimize energy consumption.

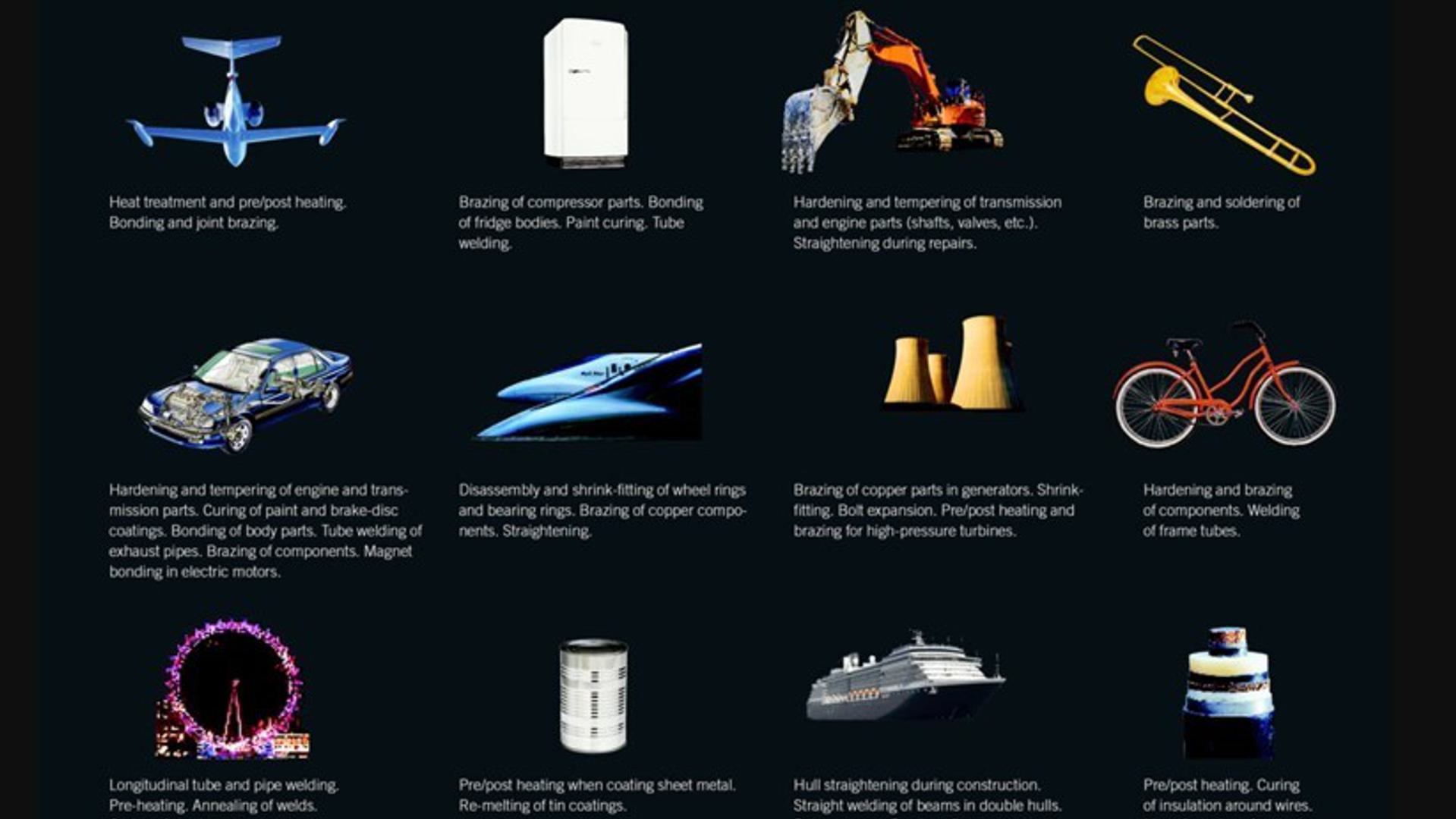

What is induction heating used for?

An induction heater comes from the word electromagnetic induction. It is a flame free, non-contact heating of medals. From aerospace to automotive manufacturing, induction heating offers energy efficiency, precision, speed, and safety. Perhaps the most familiar use of induction heating is for cooking food. The technology is popular for cooking because it the fastest and most efficient method for heating. Below are further use cases of this energy-efficient technology.

The benefits of induction heating

Induction heating provides many advantages over alternative technologies like an open flame or radiation.

Induction heating is:

- Faster. The produced heat in induction heating is instant. It takes less than one second to achieve a uniform surface temperature of 1,000°C on small metal components.

- More accurate. Just the right temperature is delivered, just where it’s needed to individual workpieces. And because of the range of frequencies available, to just the right depth. Heat distribution is precise, too. We can customize induction coils to suit practically any shape or size of workpiece. Customized coils ensure optimal heat patterns with minimum energy consumption.

- More controllable. Transistorized converters and process control software give you complete control over the entire heating process. Ramp-up and dwell times can be pre-set and repeated as often as you want. Equipment can also feature in-built telemetry devices for remote diagnostics and off-site monitoring.

- Repeatable. Induction heating lets you accurately repeat your desired heating cycle. (In fact, the produced heat from a frequency converter normally varies as little as 1-2%.) You can duplicate all the key parameters: temperature, penetration depth, heat pattern, speed-of-temperature increase, etc.

- Cleaner, safer, and more compact. No gas. No open flames. No noticeable increase in ambient temperature. No excessive floor space occupied by ovens. All this makes induction heating superior to other alternatives, and, not to mention, more sustainable as well.

- More energy-efficient: Induction heating delivers heat directly to the workpiece with minimal energy loss, often achieving efficiencies far exceeding traditional methods. This significantly reduces energy consumption and lowers carbon emissions, making it a greener solution.

- Cost-effective: By minimizing energy waste, reducing setup times, and extending equipment lifespan, induction heating helps lower overall operating costs while maintaining precision and performance.

About ENRX: ENRX combines global market leadership for industrial induction heating systems (Heat) with leading technology in the high-growth market for wireless induction charging solutions for mobility and industrial applications (Charge). Industries served by ENRX include automotive, renewable energy/wind energy, pipe fabrication, electronics, cable and mechanical engineering. Leveraging decades of experience, ENRX was established in 2022 and has operations in 20 countries.